Click on each exhibitor for product photos and information

While the show will feature nearly 200 exhibitors, this page includes those that responded with pre-show publicity information.

New FS40 series model for worlds most common shop sizes

168 Manufacturing, a brand of Precision Tool Technologies that designs and develops CNC machine shop automation technologies, announces its new FS40 series of FullShop™ Automated Coolant Management Systems. Optimized for the most common CNC machine shop sizes, the FS40 enables these shops to take their productivity to the next level. Due to its modularity, one FS40 system can automate a few CNC machines or expand to accommodate up to 40 CNC machines.

Like our flagship FS120 system, the new FS40 series monitors and replenishes all CNC sumps with optimized top-off ratios. This turnkey system is easy to install and consists of a centralized pumping station, controller, distribution manifolds and level sensor that drops into the machine tool sump. Compared to the FS120, which has a footprint of 50 by 60 inches, the new FS40 is even more compact — 30 by 30 inches.

Other features of the FS40 include:

- A modular concept that supports five remote fluid nodes

- Per CNC concentration control: top-off at 0.5 to 20 percent

- Collaborative with our FullShop coolant health app

- Industry 4.0 features — e.g. remote operation and teleservice

- Simple low-cost installation

Like the FS120, the new FS40 enables unattended CNC operation, bringing “lights-out” capabilities to machine shops. Now, instead of operating one or two shifts a day with a shop full of operators, these shops can run high-volume jobs unattended overnight, keeping the spindles spinning 24/7 and unlocking greater productivity.

New FullShop Coolant Health App

Featuring

A full range of tags, labels and specialty digitally printed items. Many different paper and synthetic materials are used along with many options of adhesives. Badger is a custom printer of functional tags and labels used in the manufacturing industry. Metalphoto capabilities have also been added. We simplify the complicated.

ZEISS T-Scan Hawk handheld laser scanner

New ZEISS T-Scan Hawk handheld scanner with three integrated lasers, each optimized for different needs: large area, fine details and hard to reach features. Photocentric LC-Magna 3D Printer which uses LCD light to print parts rapids and accurately. Large 21″ x 11″ x 14″ build volume at a fraction of the cost of SLA.

Kitamura HX250iG HMC,

Other Featured Products

- Milltronics VM5020EZ VMC with Acieta Cobot

- Mitsubishi MV1200R Wire EDM

- Kira PCV-30 VMC

- SMEC SL2000BSY Lathe

- Chevalier FSG-1632ADIV Grinder

- ZEISS Duramax HTG CMM

- Photocentric LC-Magna LCD 3D Printer

- Perseo Erie EDM Drillmate DM22iA

- Hermle USA Inc

- VICIVision M309 Shaft Measurement System

Exact Co-Tender

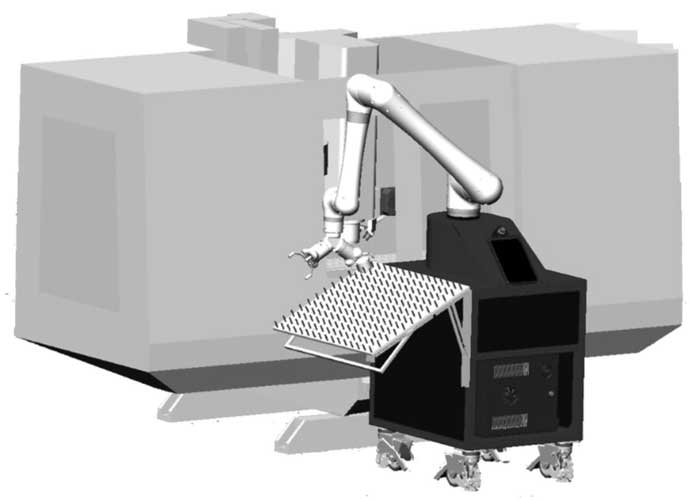

We will be showcasing the Fanuc CRX collaborative robot on our new Co-Tender machine tool tending platform. We will also be showcasing a cell with random bin picking capabilities utilizing a Fanuc LRMate and IRVision.

Exact Co-Tender Features

- Offers a low cost, easy to implement machine tending solution.

- Quickly deployable in a customer plant to load/unload CNC machines, perform light assembly or even perform unique processes such as cake decorating.

- Portable: allowing it to be moved from machine to machine based on demand.

GigaTrak Tool Tracking

GigaTrak Tool Tracking is a tool management software solution that allows a company to manage an unlimited number of Tools, Assets, Equipment, and Inventory. Track tool information, location and usage, and repair history with the scan of a barcode or RFID tag on the tool.

GigaTrak Tool Tracking has a mobile application for Android or iOS devices allowing customers to do transactions on the go away from a PC workstation. Customers are able to utilize their own cell phone or tablet to scan a barcode with their device’s camera making tool management efficient and easy.

LUBE-TECH LUBE-KUT ADVANCE

A high performance, chlorine-free cutting oil suitable for use in a wide variety of applications and on all materials. It uses a synergistic combination of extreme pressure additives to provide excellent tool life and part finish in every operation. It’s high-quality base oils and powerful antioxidant package reduce downtime and maintenance costs by providing unparalleled fluid life.

Industrial Services:

- Sump Cleaning

- Coolant Monitoring

- Filtration

- Cutting Oils

- Waylubes

- Hydraulic Oils

Enviro Product Line

100% Vegetable base stocks, biodegradable, bio-based fluid, environmentally friendly.

Featured Products

- Shibaura BTD-100.R12

- Hyundai Wia SE2200LSY & KF5600II

- Maier MLK32E

Specializing in: Boring Mills, Lathes, Machinery repair & service

Omega Matrix 4.0 - Powerful Tool Management Solution

We are announcing Omega Matrix 4.0, a robust affordable tool management solution. It is a 2D barcode reader that automates the process of getting too information into lathes/mills/CNC tools. Made in USA.

Omega Fortis Pro - 3 Axis CNC Automation

Featured Products

- Hwacheon D2 5 Axis Machine with 8 Station Multi Pallet System (Built-in Automation)

- Hwacheon Cutex 160A CNC Turning Center

- Hwacheon UM+ High Precision Vertical Machining Center for High Accuracy work

- Eagle Fiber Laser: World’s faster and only 20kw production machine

- Grob Five Axis High Precision Horizontal Milling Machines

Index Traub

- CNC turning machines

- Automatic lathes

- Multi-spindle lathes

- Turn-mill centers.

CMS

- CNC machining centers

- Thermoforming machines

- CNC routers and waterjets

Featuring

A variety of custom tube and pipe bending, laser cutting and end forming techniques used for applications in the agricultural, auto, food & beverage, medical and healthcare and recreation industries.

New Laser Cutting Equipment

Increased Demand Fuels Major Capital Investment.

To complement the existing machine technology at its Wisconsin-based facility, Sharpe Products has recently installed a BLM GROUP LT7 4 kW laser cutting system. This equipment cuts round, square, rectangle and open profile pipe or tube up to 6-inch O.D.

Adding to Production Capabilities

New Equipment to Help Serve a Diverse Customer Base.

Sharpe Products is adding to its stable of machine technology with an eighth Unison bender. This additional 80 mm all-electric CNC bending machine will help to increase production capacity for a diverse customer base. This model is ideal for the strict tolerances frequently specified for parts used in the aerospace, automotive and medical industries.

Accelerating Productivity With 3D Robotic Laser Cutting Equipment

New Machine Technology Offers Precision For Complex Components.

Sharpe Products has purchased a BLM GROUP LT-FREE laser cutting system. Built for complex, three-dimensional part profiles, the five-axis, 3 kW fiber optic laser has additional features such as robotic part manipulation and dual access part loading capabilities.

Celebrating 30 Years

Success Attributed to Ongoing Expansion And Focus on Machine Technology.

Part of the thriving metal fabrication industry, Sharpe Products of New Berlin, Wisconsin is celebrating three decades of business. Starting in 1990, on the outskirts of Milwaukee, the company began with a focus on architectural handrail fittings and metal fabrication for a variety of regional customers. Over the next years, seeing increased market demand for custom tube bending, it began to expand into more complex tube forming as well as laser cutting, servicing customers in the aerospace, agricultural, automotive, medical device and recreation industries.

Featuring

The Cybersecurity Maturity Model Certification (CMMC) program serves as a method of verifying appropriate levels of cybersecurity controls. These controls must meet the specific standards in place to protect Controlled, Unclassified Information (CUI), and Federal Contract Information (FCI), that may be held on the DoD’s industry partners’ networks in order to maintain and obtain government contracts. By 2026, organizations will have to meet certain CMMC criteria in order to bid against any Government related job.

As a provider for many manufacturing entities, SWICKtech is committed to reaching CMMC Level 3 by the end of 2021. Our team of senior industry experts are early adopters of the CMMC program, closely following its development and roll-out from day one. SWICKtech is a Registered Provider Organization (RPO), and has 2 of its own Registered Practitioners (RP) designated by the CMMC Accreditation Body (CMMC-AB).

New Techna-Check PM2 Production Monitoring System

- Universal design allowing easy connection to most machines

- Increases productivity by monitoring down time, running time, scrap count, and machine malfunctions

- Maximizes production and minimizes manufacturing errors with real time monitoring so problems can be immediately addressed

- Help reduce product costs by decreasing inefficiency in the manufacturing process

- Automatically gathers production information from the machine

- Calculates and displays OEE data

- Sends an automatic email if a machine goes down

- Option to require operator to enter a loss code to account for machine down time (customizable loss code examples; down for maintenance, waiting for material, machine setup, etc.)

MAGIDO Rotary Basket Parts Washers

The perfect choice for batch cleaning parts with hard to clean geometry. During the wash cycle, the rotating basket is power-sprayed by optimized wash nozzles and immersed in the detergent bath to ensure uniform cleaning and completer removal of contamination.

We specialize in solving complex cleaning challenges commonly found in Production manufacturing, maintenance/re-manufacturing, overhaul applications, and virtually and virtually any industry the needs to clean parts efficiently.

Dormer Pramet Precision Twist Drill MRO Cutting Tools

Cutting Tools for Maintenance and Repair Applications (MRO)

The team at Dormer Pramet has created a specific selection of cutting tools and accessories aimed at the MRO professional and sold under the Precision Twist Drill brand.

Targeted at delivering MRO professionals an offer that is easy-to-select and comprehensive for their needs, our experts have identified drills and rotary burrs that will deliver reliable and cost effective results in portable and machine applications in a wide range of operating conditions in various materials.

The selection of drills in the program includes stub, jobber, mechanics lengths and S&D reduced shank drills. To cover the breadth of applications within the MRO segment, there are drills for general purpose machine and portable drilling. These include the popular HSS R10 series for right hand drilling and HSS L10 series for left hand drilling. Also included are the carbide DC series of center drills. There is a specific selection for sheet metal drilling and spot weld drilling.

The drill program is highlighted by the MRO drills that cover most ferrous applications and are suitable for use in portable drilling, drill presses and other operations within this segment. The MRO drills are available in jobber length (301JD style), heavy duty jobber length (331HD, 332HD, 333HD styles), mechanics length with “tri-flat” shanks (321MD style), stub length (311SM, 312SM styles) and reduced shank (341SD, 342SDT styles). Within this offer there are different surface treatments to cover the wide range of MRO operating conditions. As well, the program contains conventional 118-degree point geometries as well as 135-degree self-centering split points for more challenging applications. Sets within each style are available in a rust resistant, water and shatter proof case for easy carrying and all-around use.

Dormer Pramet T8430 New Turning Grade

Pramet launches new flagship turning grade – T8430

The team at Dormer Pramet have upgraded the flagship Pramet PVD grade T8330 with a new coating generation, providing increased durability and performance.

The T8430 has quickly been marked as the most versatile grade in the Pramet assortment for general turning and heavy roughing, even in unfavorable conditions.

Developed for steel and cast steel, the Pramet grade also performs well in stainless steel, cast iron and super alloys.

A multi-layered PVD coating optimized for increased productivity, the T8430 provides up to 69 percent more durability, especially when machining raw steel blanks or difficult materials, such as Inconel and Stellite.

A unique Titanium-Boron-Nitride (TiBN) top layer offers build-up edge reduction and improved performance, while a thick TiN coating gives low compressive stress for crater wear resistance.

In addition, the hard AlTiN of the T8430 secures flank wear resistance, with a bright gold TiN layer to support wear detection.